SMALL DETAILS, BIG IMPACT.

We make it easier for more companies to produce hosiery in a more sustainable way

There’s a saying that goes a little goes a long way.

That it’s the small steps — putting one foot in front of another — and being consistent day in and day out that has the power to make a transformative difference. This is the philosophy we based Treadfine on — that we need to tread lightly and reduce fashion’s cumulative impact on the environment by making more mindful choices, and focusing on quality and longevity.

Because making sustainable change in the industry requires transformation at scale. Going beyond the pilot project, we believe that we can leverage our knowledge and expertise to make it easier for more companies to produce their hosiery in a more sustainable way.

We want to partner up with changemaking brands and companies who not only want to provide their customers with a better quality product, but who want to deliver on their sustainability commitments in a real and tangible way. Better for the customer, better for the company’s bottom line, and better for the planet.

About Us

Partnering with Treadfine means investing in a more durable product that embodies responsible production practices. Our offerings feature sustainable material certifications, ensuring that each item is crafted with care for the environment. Proudly made in Italy and designed in Sweden, Treadfine products come in certified minimal and sustainable packaging. Treadfine is owned and operated by SWE-S, with more than 10 years’ experience in sustainable hosiery production.

Our Mission

Using our expertise to replace wear-and-tear nylon products with more durable and responsibly produced legwear — giving consumers, businesses and the planet a better alternative to traditional hosiery products.

Our Facilities

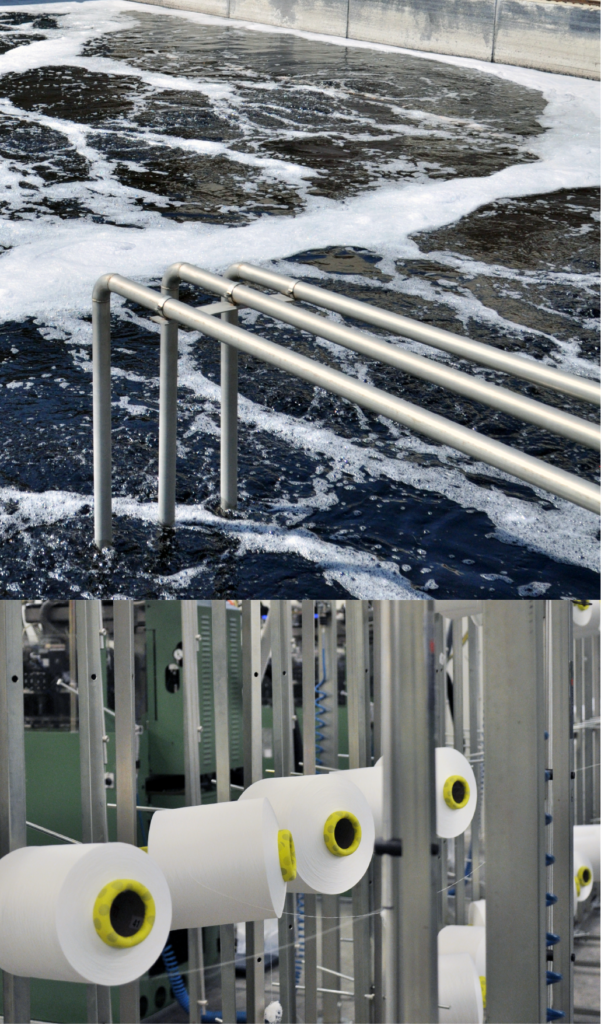

Our production facilities are based in Italy, where we have a long-standing partnership with our suppliers. Our factories only use energy from renewable resources, such as wind and solar panels and water is treated for reuse or release on site. Our factories hold the highest standards of environmental and ethical production.

RENEWABLE ENERGY

Our factories are powered by renewable energy in the form of wind or solar panels, producing 35-80% of their own energy. In case of limited supply, The remaining energy is derived from renewable certified third parties.

WATER TREATMENT

Our dyeing facilities uses equipment resulting in 20% less energy consumption and reuses 50% of the water. The other 50% is purified, leaving it fit for use or release into the environment after one week.

Swedish Stockings Recycling Program

Working with Treadfine also gives you the option of joining a nylon waste takeback program owned and operated by Swedish Stockings.

Read more about it here.

TALK TO US

Have any questions? We are always open to talk about your business and how we can help you.